Auxiliary processing series

+86 18322071688

Since the launch of the Sanhao Baozi and Dumpling All-in-One Machine on the market, many catering practitioners and entrepreneurial veterans have continued to pay attention. From 'Can we really take care of making steamed buns and dumplings' to 'What categories can we expand?' Everyone's questions and suggestions have always been the core driving force for Sanhao's iterative upgrade. After market inspection and technical precipitation, the Sanhao steamed stuffed bun and dumpling all-in-one machine is now undergoing a major upgrade. It is comprehensively optimized in three dimensions: welding process, system operation and head function. It also adapts its small size to multiple scenarios, providing stalls and supermarkets. Business models such as mom-and-pop stores inject new vitality. For catering equipment, the durability and standards of the fuselage directly affect the operating efficiency and use of

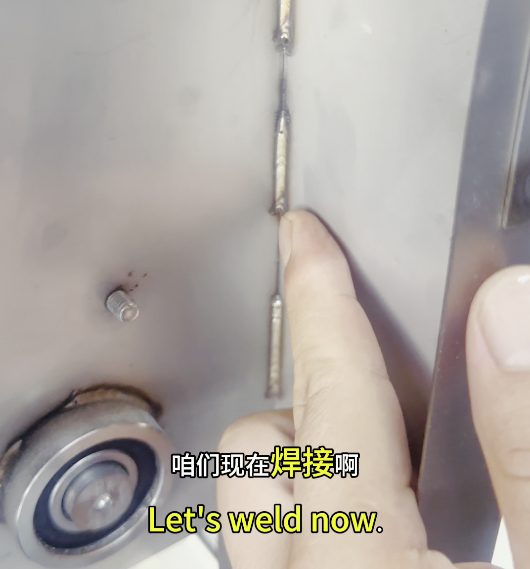

With this upgrade of , Sanhao abandons the traditional welding method, adopts laser welding process, and matches it with high-quality stainless steel welding wire to solve the two major pain points in the use of the equipment from the root cause.

traditional welding process is prone to rough and uneven welds, which not only affects the appearance of the equipment, but also easily hides dirt and dirt. After long-term use, it may also cause rust due to oxidation, which increases cleaning difficulty and maintenance costs. With its high-precision and high-energy characteristics, laser welding can make the weld seam appear smooth and delicate without obvious bumps or gaps. It only needs to be simply wiped during daily cleaning, which greatly reduces the pressure of health maintenance. At the same time, the addition of stainless steel welding wire further improves the corrosion resistance of the weld.

had feedback from many veterans before that the operating interfaces of some stuffing equipment were complex and required repeated learning to master the production settings of different categories. In response to this pain point, Sanhao deeply optimized the equipment system, and the upgraded PLC interactive system made the operating process clear, convenient and efficient.

upgraded system interface is presented in an intuitive combination of icons and text. Users do not need to remember complex operation steps. They just need to click the corresponding function wants to make dumplings, click ' Dumpling Mode 'and if you want to make buns, select Dumpling Mode '.

The system will automatically match the corresponding production parameters, and accurately control the entire process from the proportion of flour and filling to the forming speed. Not only that, the system also supports simple parameter fine-tuning. If Lao Tie wants to adjust the thickness of the skin according to local tastes, he only needs to gently slide the button among the corresponding options to complete the setting, truly realizing

What you see is what you get. ', even a novice to the equipment for the first time can operate it skillfully in a short time. While satisfies the basic operation convenience, Sanhao pays more attention to the equipment ' Inclusive '-how does make one machine meet the stuffing needs of different regions and different categories? With this upgrade, Sanhao has achieved new breakthroughs in head research and development. It not only retains the previously well-received ' slider head replacement technology ', but also further expands its head pattern development capabilities. Now it can support the production of rectangles, squares, circles, ovals and various irregular stuffing products.

Whether is the Yuanbao dumplings common in the north, the triangle dumplings favorite in the south, or the oval vegetable buns with local characteristics, Sanhao can customize the exclusive machine head for Lao Tie as long as it provides the flour filling formula and forming requirements, turning a device into

What's more considerate is that Sanhao has also reduced and optimized the size of the equipment. Compared with the original product, the new version of the machine has reduced the area by about 20%

Even in a 10 square meter mom-and-pop store, stall or supermarket counter, it can be easily placed without worrying about tight space.

From the perspective of efficiency, 's performance is still strong: can make 5000 dumplings per hour, and can make 1000 buns per hour, which can fully meet the needs of the morning rush and dining peak season. Food delivery needs not only reduce labor costs, but also avoid customer loss caused by low manual production efficiency.

Lao Tie in front of 's screen, if you are operating a stall, supermarket counter or mom-and-pop store, and want to operate multiple categories of steamed buns, dumplings, and special stuffing products through the Dumpling All-in-One Machine , or if you have more questions about the equipment's welding process, PLC

system, and machine head customization, please leave a message in the comment area or send a private letter to the three good. What other stuffing categories do you want this machine to unlock? Or what problems have you encountered while using the equipment? Let's chat together. Sanhao is always willing to continue to polish more practical's new good equipment according to everyone's needs!

+86 18322071688