Auxiliary processing series

+86 18322071688

As a catering practitioner, what are you afraid of when purchasing a dumpling machine? It was not that he was worried about spending money, but that was afraid that he would spend money to buy an 'embroidered pillow'-the advertisements were hyped up, but in actual use, the filling would be jammed or the dumplings would be crooked. The output in a day would not be able to keep up with the manual labor. then piled the machines in the corner and dropped dust. Sanhao believed that the old man in front of the screen must have thought about these issues.

said that choosing a dumpling maker is actually not that complicated. You don't have to stare at the fancy 'multi-function' gimmicks, and don't be fooled by the low price. Today, let's take Sanhao 460 Dumpling Machine as an example to give novice Xiaobai and catering practitioners a taste: What should see in a truly useful dumpling machine?

chose the machine first to look at its appearance, not because of how beautiful it looked, but because of the

some manufacturers have crooked ideas on plate materials in order to keep prices down: thin iron sheets are used to fill thick steel plates, which will deform in just two months of use; and the joints are cut corners and rust when they are stained with water. You know, the dumpling machine deals with flour and fillings every day. The moisture is heavy and the friction is high. If the plates fail to pass the test, there is no guarantee for hygiene, let alone durability.

How does judge whether the plate is good or not? You don't need to take professional instruments. You can feel it by tapping and touching it with your hands.(non-professional advice)

For example, the Sanhao 460 Dumpling Machine is made of high-quality

stainless steel. The sound when knocked is thick and smooth, without burrs, and the corners do not have the sharp feeling of cutting hands. This kind of plate is not only resistant to corrosion and easy to clean, but even if it works with high intensity for a long time, the body will not shake or deform (the plate number is 3 thick, and the actual thickness is 2.75).

remembers: doesn't feel like a good machine even if he doesn't want to use good plates. Plate is the foundation, but the foundation is not solid, and no subsequent functions are just empty talk. , if plate is 'face', then details are the' lining 'of a good machine. Many dumpling machines have problems while using . They are either major problems or the details are not done properly.

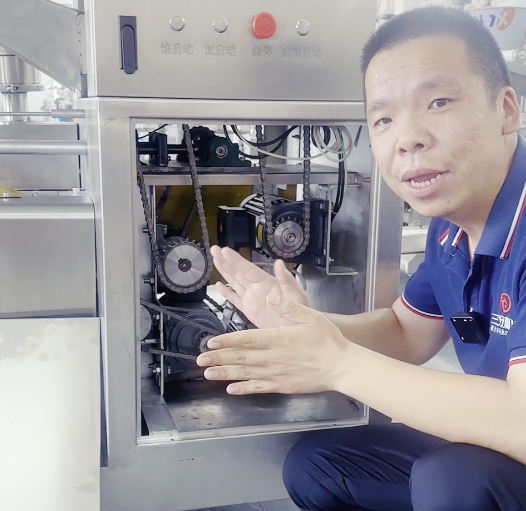

How does see the details? Focus on these places: - solder joints and welding process: Good machine solder joints should be uniform and full, with no traces of missed welding or false welding. For example, the fuselage connection of Sanhao 460 is laser welded, and the weld seam is as smooth as a line. It is not only beautiful, but also prevents stuffing residue from getting stuck in the gaps and reduces cleaning trouble. If he sees crooked solder joints with obvious air holes, will have to think deeply at this time.

Processing of the - shaft and scraper: The shaft is the core that drives the machine to run, and the scraper is responsible for feeding dough and stuffing. The processing accuracy of these two parts directly affects the stability of the machine. The shaft diameter of Sanhao 460 is 2mm larger than that of ordinary models. The surface has been second-polished and anti-corrosion treatment. Even if it comes into contact with wet surfaces for a long time, it will not rust and jam; the edge of the scraper is polished and has no burrs. When feeding, there will be no '', which is cleaner than being scraped by hand.

-The intention of 's small parts: for example, whether the screws are rust-proof, whether the protective cover has reserved cooling holes, and whether the buttons on the operation panel are sensitive. These seemingly inconspicuous small places can just tell whether manufacturers have a 'die-to-die' attitude. For example, during the testing stage of Sanhao 460 Dumpling Machine, repeatedly adjusted the optical axis and scraper 12 times, just to make every small part 'easy to use.' The reason why chose the dumpling machine

was to determine whethe was easy to use and whether it could improve efficiency. This made controllability impossible. Many novices only look at the 'yield' when buying a machine, but ignore the 'adjustability'-different fillings, different flour, and different taste requirements require the machine to 'follow suit'. This is really 'easy'.

dual motor + light sensor probe, the surface rail adjustment is accurate enough: the surface rail is the key to determining the thickness of the dumpling skin. Ordinary machines only have one motor to control the dough stick. Either the dough is too thick to cook, or it is too thin and easy to break. Sanhao's new 460 dumpling machine uses two dough sticks, each equipped with a motor for , and a light-sensing probe is added in the middle. The probe can detect the thickness of the dough in real time. The two motors coordinate the rotation speed according to the data. Whether it is soft or hard, the dough can be uniform and consistent, and there will be no 'thick one side and thin', (the gap between the dough sticks uses a graduated handle).

controls the stuffing, and the stuffing is adjusted enough: when making different dumplings, the stuffing is somewhat different-you need to put less leek and egg stuffing to avoid squeezing, and you need to put more cabbage and pork stuffing to make it more delicious. The filling system of the 460 Dumpling Machine is controlled by the exclusive motor + frequency converter. The filling amount can be accurately adjusted by turning the knob, from 'small stuffing exquisite style' to 'large stuffing satisfying style.'

can adjust the head speed, which is highly adaptable: many people don't know that the head speed affects the dumpling forming rate. The extension of the flour varies with the draught of flour-the flour with more draught is soft, and it is easy to 'tear' when the nose turns faster; the flour with less draught is hard, and it is easy to 'miss angle' when it turns slower. Sanhao 460 Dumpling Machine sets the head to be controllable and adjustable, and adjusts the speed according to the flour state. The vegetarian fillings, meat fillings, frozen noodles and fresh noodles can be adapted, and the forming pass rate is stable at 98% or more (under suitable conditions) .

What is more considerate about is that the 460 Dumpling Machine is also designed with multiple models. It only takes 15-30 seconds to change the machine head-make dumplings today, and if you want to make pot stickers and steam dumplings tomorrow, you can start with a different machine head. You don't have to buy a special machine, which is practical for small restaurants and chain dumpling restaurants.

chooses equipment, he chooses ,hardcore player is caterer doesn't make money easily. chooses equipment not cheap to get but buy peace of mind, buy efficiency. As I said at the beginning, some manufacturers play 'word games' and blow 'as long as it can be packed' into 'multi-functions', but when it comes to the kitchen, even the vegetarian fillings cannot be packed smoothly.

if the old man in front of the screen is choosing the dumpling machine when selects the dumpling machine, he might as well follow the three criteria of 's Three Good Things and ask: Is the plate thick enough? Are the details not handled properly? Can various parameters be finely adjusted? Here, the best

also wants to ask the old iron people: What pits did you step on when buying a dumpling machine? Or what else do you think you should look at when choosing a dumpling maker? Talk in the comment area!

+86 18322071688